Hobby Applications

Hobbyists and Woodcarving

Power tools have become more common in recent years for woodcarving and hobby applications. A flexible shaft machine along with a variety of burs makes the perfect combination to produce high-quality crafts items.

Woodcarvers find that power tools help to remove wood quickly, with minimal fracturing and breaking. Carvings can be thinner and more detailed, and they can be produced with less difficulty than when using edge tools. Flexible shaft machines can rough out a carving as well as be used to do the detail work. Burs are used to remove wood, as well as to carve and sand wood and other materials.

Burs are available in many shapes and sizes. While a ball-shaped bur may be used to hollow out an area, a flame-shaped bur could make concave cuts, or a taper could get into tight areas. The burs are usually made of materials such as steel, carbide, ruby, diamond, or stone. Some are designed with edges that cut like a rotary file; others have a finer grit that gives a smoother finished product.

Hobbyists, too, have found that a flex shaft machine is a very versatile tool. Not only can it be used to drill holes and grind materials such as wood and plastic, but it can be used with various burs and cutters as well. While many hobbyists craft model airplanes, boats, or dollhouses, those hobbyists that fashion jewelry may want to read about Jewelry Making Applications.

Woodcarving Bur Applications

The following chart describes some of the various woodcarving bur applications.

| BUR | BUR DESCRIPTION | BUR USE |

|---|---|---|

| Round | round/ball shape |

hollow out areas

create concave cuts make indentations in wood |

| Pear | pear shape | round edges |

| Oval | oval shape |

round edges

make concave cuts |

| Flame | long/slim bud shape |

make v-cuts

make concave cuts create detail |

| Inverted Cone |

wider upside down cone shape,

tapers toward the shank |

make v-cuts

create texture |

| Wheel | wheel/disc shape |

make channel cuts

remove unwanted wood undercut detailed areas |

| Flat End Cylinder | cylinder shape, straight sides |

cut flat areas

round edges make v-cuts |

| Round End Cylinder | rounded end cylinder shape |

hollow out areas

make concave cuts round edges cut flat areas |

| Taper | tapered cone shape |

access hard-to-reach areas

round edges make concave cuts |

| Drill | twist drill shape |

drill holes

use for carving |

| BUR MATERIAL | BUR DESCRIPTION | BUR USE |

|---|---|---|

| Carbide | points in many shapes |

remove wood

roughing out |

| Carbide Cutters |

regular, double, coarse cut

fine, very fine cross cut many shapes |

material removal

creating detail finishing |

| High-Speed Steel | many shapes |

countersink

cut grooves |

| Diamond | plated or sintered in many shapes |

carve fine details

use for final shaping |

| Ruby |

ruby particles bonded to metal

many shapes |

removing wood

leave smooth finish |

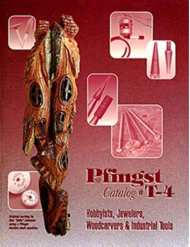

Left: Our T-4 Catalog cover highlights an original carving by Ron “Odin” Johnson using a Pfingst flexible shaft machine.

Left: Our T-4 Catalog cover highlights an original carving by Ron “Odin” Johnson using a Pfingst flexible shaft machine.

The original carving is made out of Montana Black Cottonwood Bark. The bark is harvested from dead trees that were about 50 to 80 years old.

The bark varies from piece to piece, which makes each carving totally different and unique.

After eight trips to Europe where Ron studied castles, he began to carve them. In 1984, The Duke and Duchess of Devonshire invited Ron, together with several other artists, to carve in Chatsworth Castle in England.

Ron can be contacted for more information at P. O. Box 1333, Gig Harbor, WA 98335