Horico Sintered Diamonds - Ordering Information & Recommendations

- Ordering Instructions

- Maximum RPM

- Shank Types and Lengths

- Information on Shanks and Grits

- Safety Instructions

- Diamond Disks

Ordering Instructions

By indicating the quantity, type of shank, grit and size, prompt and accurate deliveries of your HORICO requirements will be assured. See below for RPM information.

Grit Abbreviations —

X = Extra Coarse Grit

F = Extra Fine Grit

G = Course Grit

U = Ultra Fine Grit

C = Fine Grit

For Example —

"FG019G012" would be determined from the following:

FG = Shank

019 = I.S.O. Number (Shape)

G = Coarse Grit

012 = I.S.O. Number (Size)

Sintered Diamonds Maximum RPM

| ISO (1/10mm) | HP RPM |

|---|---|

| 016—070 | 25,000 |

| 080—220 | 15,000 |

The optimal r.p.m. recommended by HORICO is approximately 50% of the maximum permissible velocity.

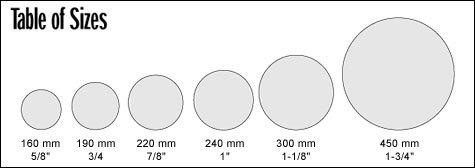

Shank Types and Lengths

The available shank types are stated near the illustrations. The overall length may vary due to extra length head or neck. As all monitors vary, we regret that none of the images in our online catalog can be to scale. Please refer to the information listed with each illustration, or request our catalog by mail, which includes images to scale.

| Abbr. | Shank | Diameter | Length | |

|---|---|---|---|---|

| HP | Handpiece | Ø 2,35 mm | 44,5 mm — 1.752 inch |  |

| RA | Right Angle | Ø 2,35 mm | 22,5 mm — 0.886 inch |  |

| FG | Ø 0,6 mm | 19,0 mm — 0.748 inch |  |

Information on Shanks and Grits

The well known HORICO DIAMOND ABRASIVES and additional HORICO DENTAL PRODUCTS are illustrated on this website. The various grits and their recommended uses are listed below.

X extra coarse grit (180µ) – black ring on the shank

Extra coarse FG diamonds are widely used for quick reduction of tooth substance during crown preparations. Finishing diamonds (C grit) are needed for smoothing as well as for the final shaping of the respective preparations. X-coarse midget diamonds are used for the removal of old fillings. Because of enamel splintering due to the usage of extra coarse diamonds it is advisable to finish with a C-grit (50µ) or F-grit (30µ) diamond.The extra coarse midgetpoints have been especially developed to facilitate removal of old crowns. These crown cutters do not chatter or “walk” across the crown, a tendency sometimes noticed when using carbides. These midget points can be used for as many as 5-10 crowns and afford real economy compared to other techniques.

G coarse grit (135µ) – green ring on the shank

In general, coarse grit instruments may serve the same purpose, but not quite as efficiently for removing old crowns. Also with this type of grit enamel splinterings will occur, making it necessary to employ finishing diamonds (either F-grit or C-grit).normal grit (100-120µ)

After cavity preparations with normal grit diamonds, finishing is not usually essential. Enamel splintering does not occur and the surface usually provides excellence adherence for filling materials such as cement or amalgam. For inlay and onlay preparations it is advisable to use C and F finishing diamonds for precise adjustment of the margins.C fine grit (50µ) – red ring on the shank

C finishing diamonds are recommended for finishing preparations and for pre-smoothing of composite materials with microfillers as well as for the removal of overhangs.F extra fine grit (30µ ) – yellow ring on the shank

F finishing diamonds are used for the finishing of preparations and for the finishing of composite materials with microfillers. They are also suitable for precise contouring or for removal of remaining overhangs.U ultra fine grit (15µ ) – violet ring on the shank

The third finishing step for composite materials with microfillers is completed with the U-grit finishing diamonds. The gloss accomplished by using the U-grit instruments provides the surface required for lateral teeth. Advantages can also be achieved by using a sequence of increasingly finer diamonds for composite materials with microfillers.C + F + U

To accomplish an optimal result it is advisable to use our C-grit (50µ), F-grit (30µ) and U-grit (15µ) finishing diamonds only whilst applying a slow speed (10,000-15,000 RPM) combined with minimum working pressure and abundant water cooling. As in other fields—such as the finishing of wood products—it is known that better results are achieved by a sequence of prefinishing, fine-finishing and polishing compared to processing material without the intermediate finishing steps. Following all steps assures the optimal high gloss desirable for lateral teeth. It will also be found that these instruments have a very long life.The use of finishing diamond for composite materials with microfiller is definitely recommended as the microfiller will not be pulled away from the matrix material-a tendency sometimes occurring when using tungsten carbide burs or finishing stones.

Safety Instructions

Please be sure to adhere to the following safety instructions when using all of our Horico® Diamond Instruments.

- Insert the shank according to the instructions of the manufacturer. Insertion should be for the full length, and if necessary use the bur changer provided by the manufacturer for this purpose. Finishing diamonds are preferably inserted without the use of a bur changer as with the new type of springloaded chucks. Diamond instruments with fine points can easily be damaged if a bur changer is used.

- Do not use the handpiece or contra angle above the prescribed velocity as per Speed Table shown below. The recommended r.p.m. should be observed.

- Full speed should be reached before operating in the mouth of the patient. Technicians should run the handpiece at full speed before application to the product on which work is being performed.

- Warning: If instruments become bent, be sure to remove them from all further use. Use of these instruments could be dangerous for the dentist and patient, as well as the technician.

- Dentists: Always use spray.

- Pressure should be 20-50 p for all FG instruments, as well as for handpiece or latch-type instruments with diameter up to 023, in other words work with as little pressure as possible. Handpiece and latch-type instruments (not FG) with diameters 025 and larger, may be used with pressure up to 500 p.

- Do not work with a pulling motion to be sure that the instrument remains firmly seated during the entire operation.

- Do not apply leverage or a twisting motion.

- Always use safety glasses.

Diamond Disks

Diamond Disks available—

Double sided:

Diamond coating on both sides

Safe Inside:

Diamond coating on outside surface, see Illustration.

Safe Outside:

Diamond coating on inside surface only, see illustration.

- Do not remove from Mandrel

- Do not use leverage

- Do not jam or bend

- Always wear protective glasses

- Do not use in the mouth